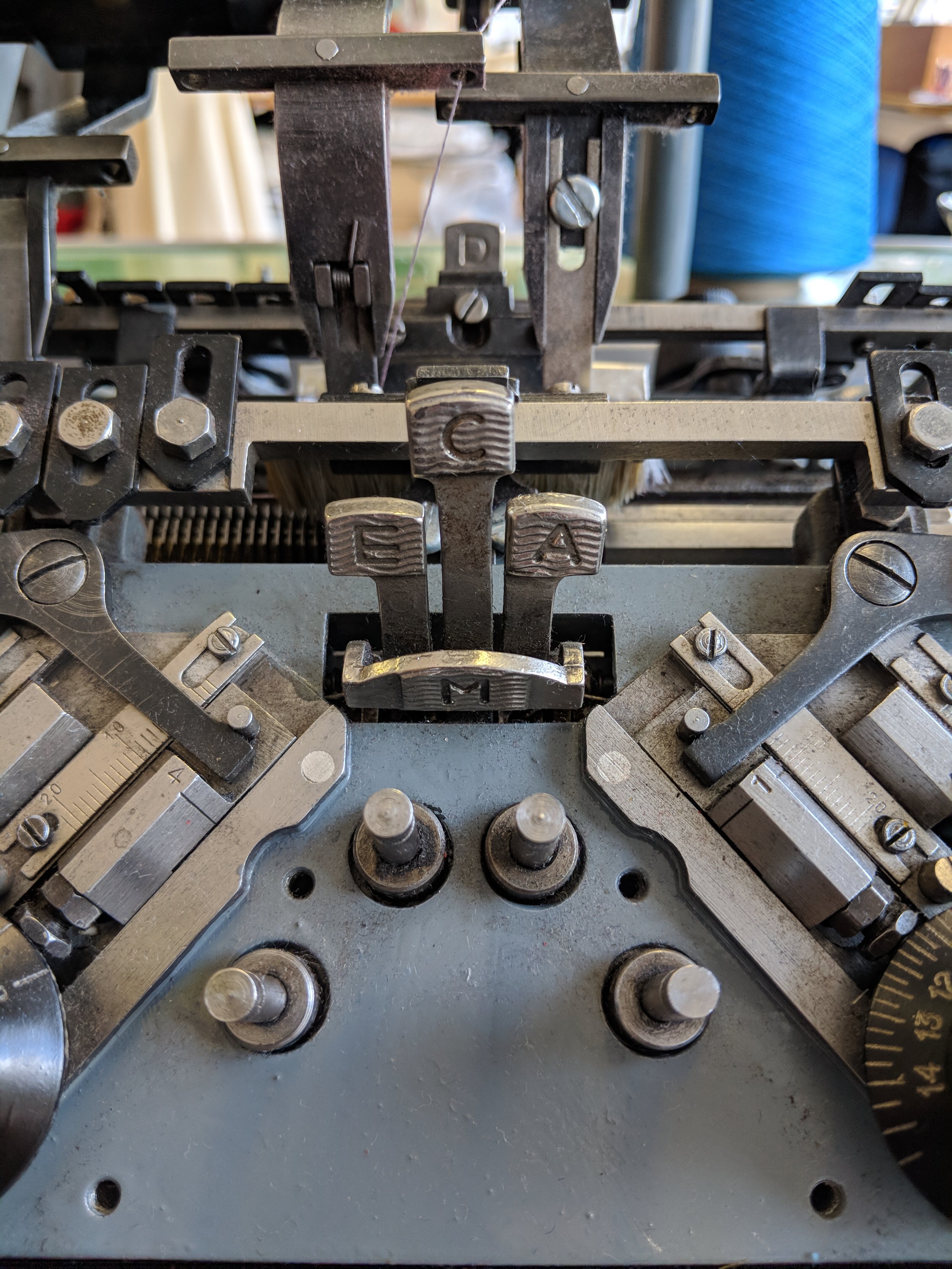

Olivia gives you insight into her Santagostino 12gg Industrial hand flat Knitting Machine on which she designs and makes everything.

What does the name mean?

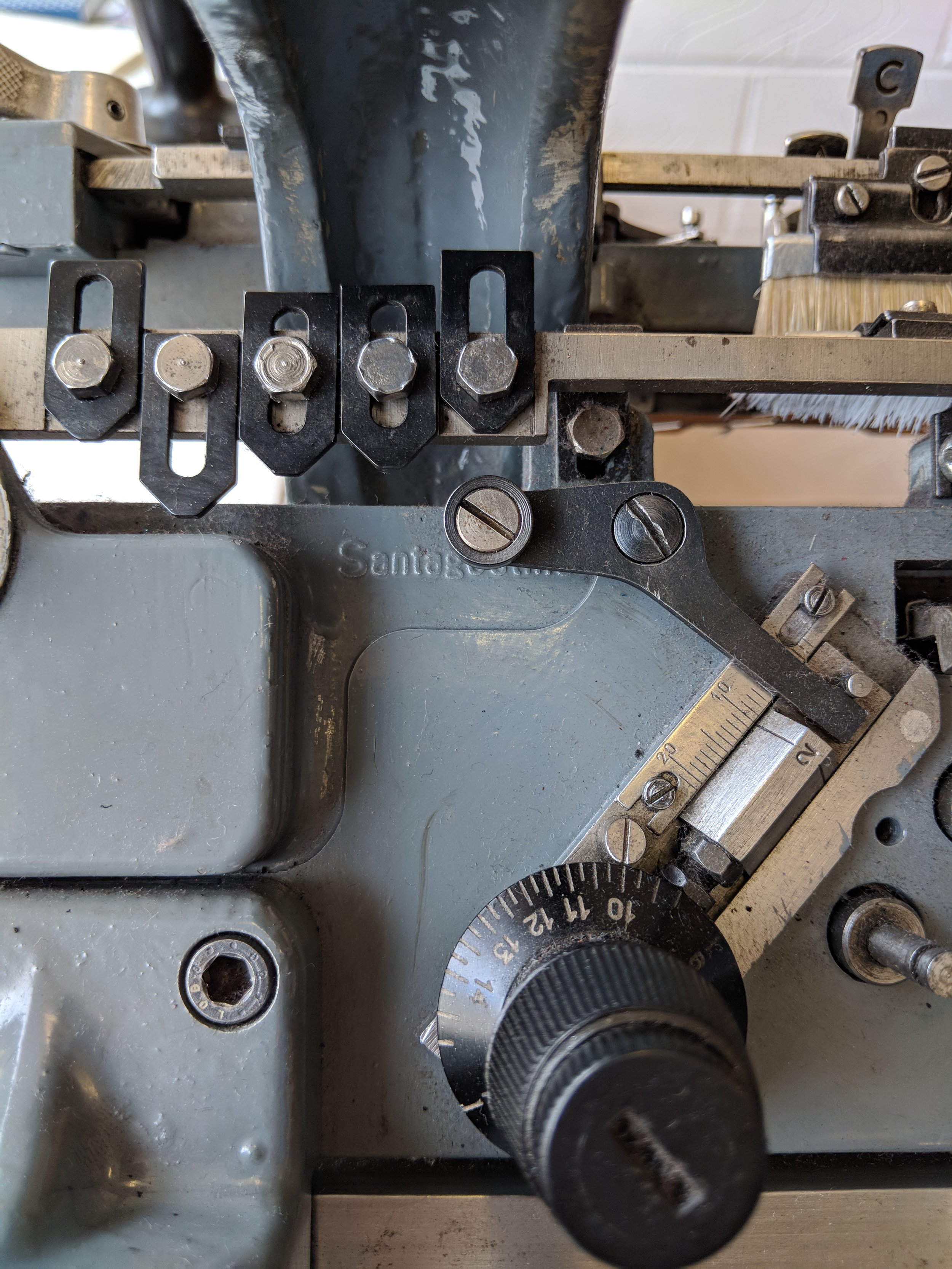

Santagostino is the brand of machine. It was an Italian company who used to make hand flat industrial knitting machines. Other brands you might hear of are are Dubied (Swiss) and Protti (Italian).

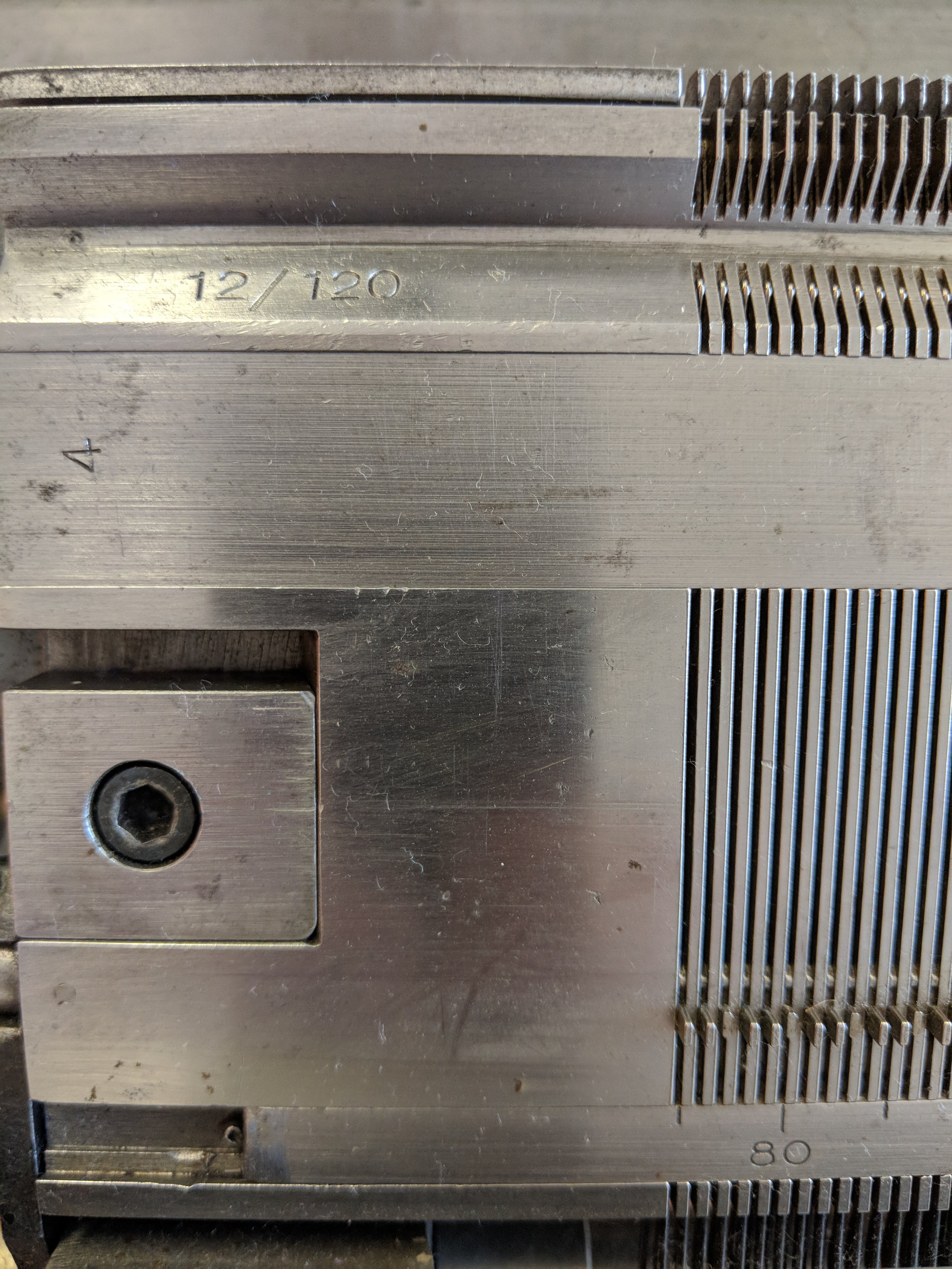

The 12gg refers to the gauge of the machine. This means that for my machine, there are 12 needles per inch on the needle bed. When the gauge is this high it means that the needles are very slender and packed together, meaning you create a fine piece of knitting. If you wanted to create chunky, thicker knitting, you would use a machine with a lower gauge, such as a 4gg.

How does it work?

This machine is totally mechanical and works by manually moving the carriage containing the yarn across the needle bed. As the carriage passes over each individual in action needle, the needle is pulled up and creates a loop from the yarn. As you progress, the knitted fabric appears below the needle beds.

By changing the colour and type of yarn, transferring stitches and selecting different knobs and bolts on the carriage, you can create a myriad of different stitches. The possibilities really are endless of designs you can creating by experimenting and combining different stitches and techniques together.

Where did it come from?

This machine was originally made 50-100 years ago and was reconditioned prior to me buying it. It is a very special piece of equipment as Knitting machines are not really made in this way any more so old ones like this are becoming more and more rare. The hand flat industrials are what used to be used everywhere in the knitting industry, however due to technological developments, the industry now uses digitalised larger versions of these machines to increase production output. The companies who design and make industrial knitting machines today only create electronic machines. With the exception of one or two bigger fashion houses who use the old hand flats to sample on, most hand flat industrials are now only used in art colleges and universities and by small, independent brands who don’t create mass produced collections.

How did you learn to use it?

I learnt to use the Industrial hand flat knitting machine whilst I was at Chelsea College of Art & Design. I specialised in knitwear and after being taught on the domestic knitting machines, we were introduced to the big bad industrials! It is incredibly hard to do anything on these machines at first as there is a lot of skill and intuition that is needed to use them which only comes with time and practise. I remember so clearly the first lesson I had being shown how to use the industrials and everyone in the class was so frustrated; none of us could knit anything that wasn’t laddered or just fell off the machine completely! However, the difficulty intrigued me and I decided that I wanted to learn how to master this piece of equipment, so from that point on I created all of my work on the industrial hand flats. It was a tricky journey! I remember specifically creating a sample which was very delicate and time consuming, I had worked on the piece for about 7 hours in total and as I was casting off I slightly lost focus, dropped a couple of stitches, the whole piece laddered, fell off the machine and crashed to the ground and I sat on the floor and cried!

I am much more skilled and confident now and am also better and noticing the signs that something isn’t quite right with the machine, the yarn or the tension and may lead to something going wrong. However even now after 3 years at university and 3 years owning my own machine, there is still so much to learn. It is what fascinates me about knitting in this way, you are always improving and you won’t ever know everything.

Want to know more?

I went live with Handmade in Britain on Wednesday 1st July, as part of their Handmade Interact series, to speak about how I started my business, my process and inspiration, as well as give a live demo on my Industrial knitting machine and show some pieces currently available for sale. Click here to watch it!

A quick time video of Olivia threading up her machine ready for knitting and casting the yarn on.

Machine Details

A snippet of Olivia making one of the Glacial Collection scarves.

This is a video of Olivia ‘casting off’. This technique is done at the end of every single piece of knitting so that the edge is sealed and the yarn doesn’t run and ladder the constructed fabric.